Industries

Hydroelectric power

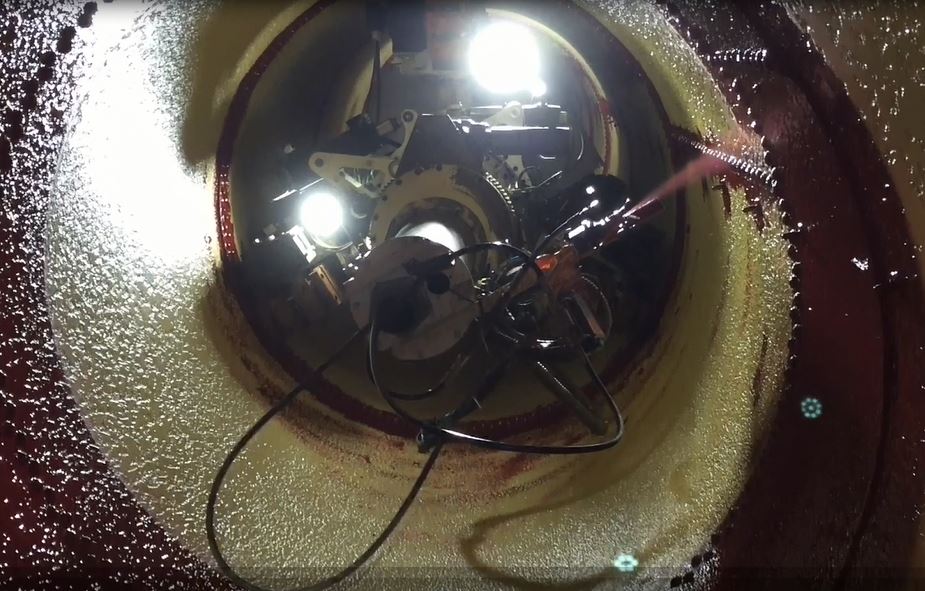

AMBPR works in partnership with ACRI Ingénierie and offers a mobile robot for stripping and painting pipes.

In the field of treatment of penstocks, current practice not only focuses on carrying out the three steps manually (cleaning, stripping, painting) but also on creating a suitable working environment.

Surface preparation

External penstock cleaning

Surface

Exterior pipe UHP sandblasting

Surface treatment

Painting the interior of the pipe

LESS IMPACT ON THE ENVIRONMENT

Stripping is carried out by a robot equipped with a nozzle that emits a jet of water at very high pressure. The nozzle is placed under a bell in order to suck up what has been stripped at the source.

This innovative source capture process minimizes the exposure of workers and the risk of dispersion of the pickled products in the environment.

Safety and health

The AMBPR robot removes containment and scaffolding. The current “pilot” version carries out the stripping but it already makes it possible to illustrate the progress compared to current practices.

The robot allows to:

- limit the confinement of the site to the treated area,

- to avoid the use of scaffolding,

- to avoid confinement in extreme conditions (slope, steep terrain},

- reducing the number of helicopter rotations required to set up site facilities.