Process

HP washing – 400 bar

The fairing of your boat is essential!

This involves cleaning the submerged part of the ship’s hull to maintain its performance and lifespan. It is also an essential step because by cleaning your boat hull you will realize the general condition of your boat and if necessary, any work to be done, it is for your safety!

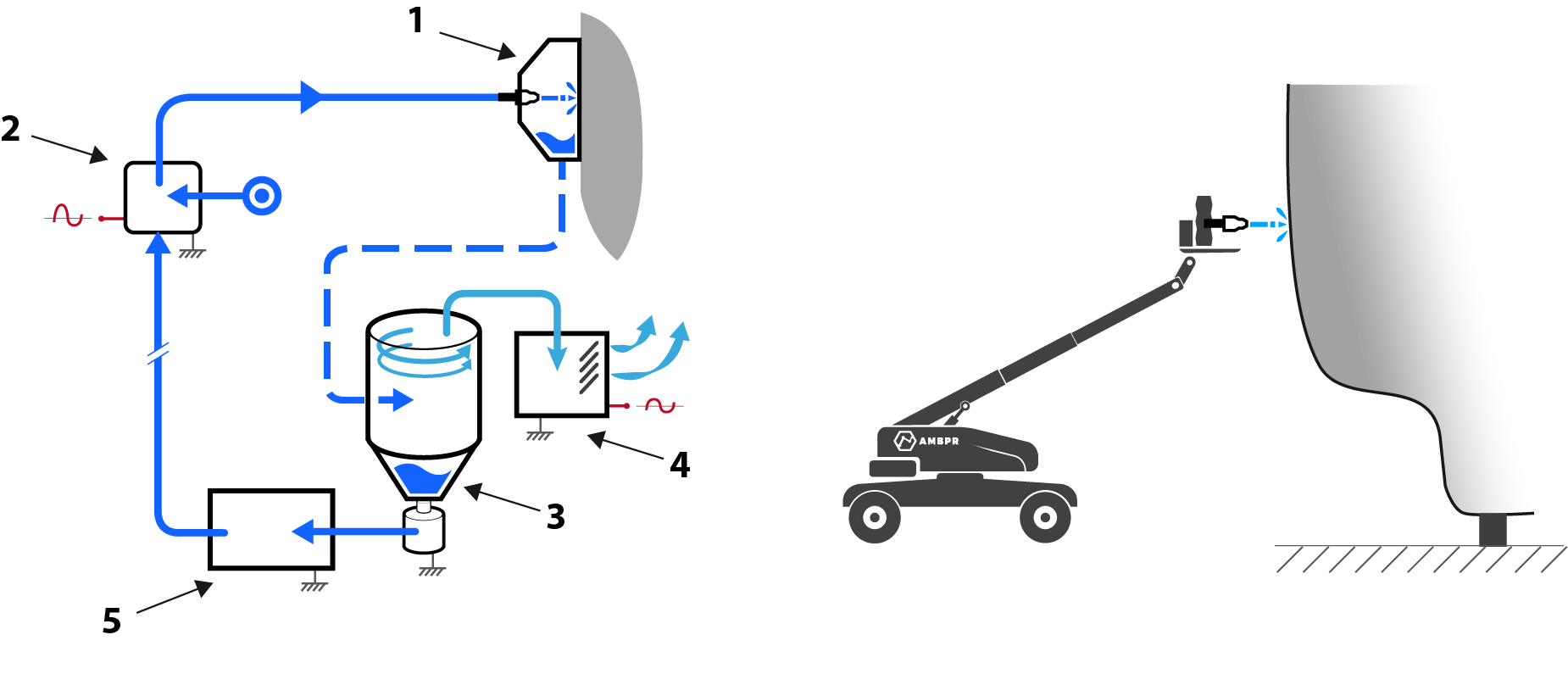

The robotic high pressure washing allows safe cleaning while maintaining a perfect projection distance with the hull. The nozzle is at a precise angle so that it can reduce the power of the jet and avoid damaging the hull and the paint coating.

Protection of operators

Increased productivity

Reduce vessel downtime in dry dock

Collection and treatment of waste

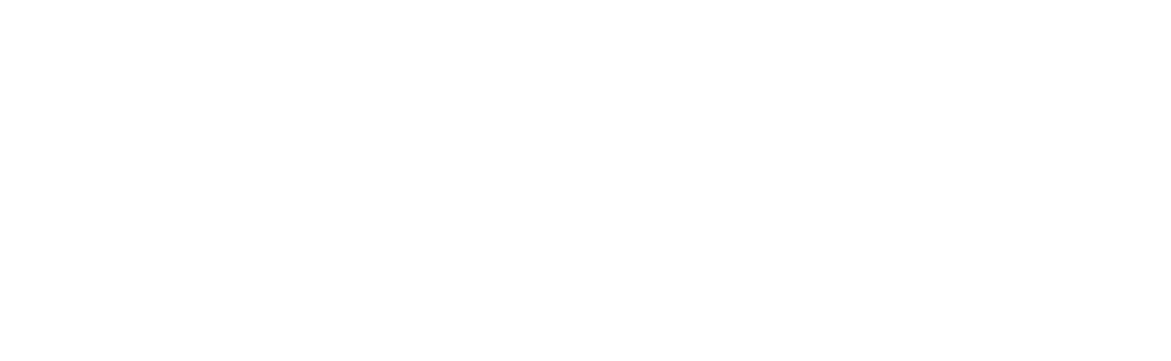

1 – High pressure gun with flat jet nozzle mounted on the tool holder of the robot

2 – High pressure pumping system

3 – Silo and water treatment system to the container: pollution control

4 – Suction system

5 – Nomad’o container

– Free jet 1 Flat or Rotary head

– Free Jet 2 Flat or Rotary heads

OPTION:

- Capture at the source diameter 300 mm,

- Vacuum system,

- Water treatment

Motor: Electric 30 kW direct start

Max pressure: 400 bar

Max flow: 40 L / min

Weight: 830 Kg

Dimensions (L x W x H): 1500 mm x 865 x 1450

Power: 30 kW

Power supply: 400 V / 50 Hz or 440 – 460 V / 60 Hz

(Connection by means of a CEE 63 A connector)

Motor: Electric 45 kW direct start

Max vacuum: 0.6 bar

Max flow rate: 2100 m3 / h.

Weight: 2090 Kg

Dimension (L x W x H): 2450 mm x 1200 x 2320

Videos

Robot washing process shipyard – DAMEN