Process

UHP water sandblasting

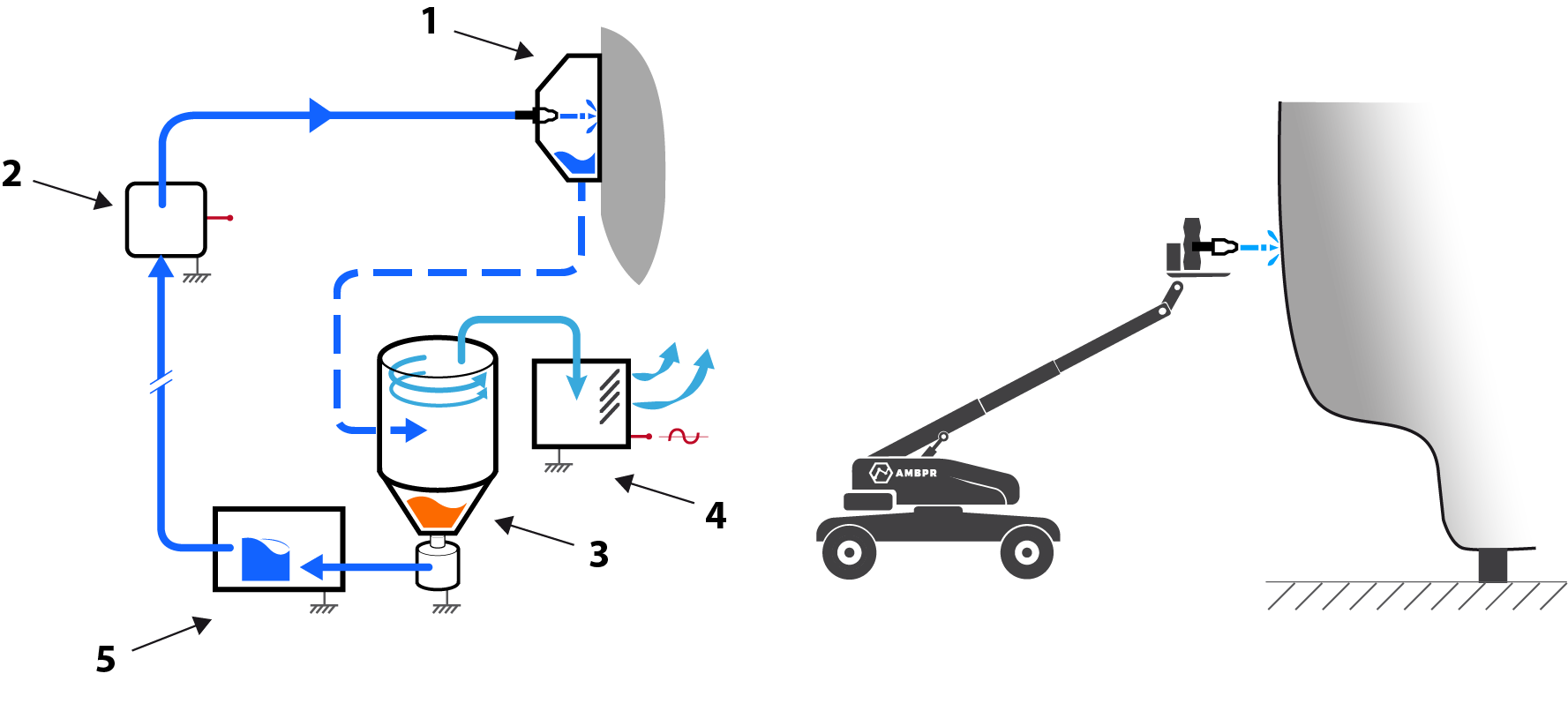

Thanks to its pressurized water projection at 2500 bar via our robotic solution, this process makes it possible to strip a coated surface and find the original profile of the metal support. This method is particularly suitable for work on site with high quality and restrictive environmental requirements.

This pickling technique has many advantages:

• protection against splashes of particles, grease, rust, traces of paint and coating that could cause injury or poisoning.

• reduced water consumption thanks to our water recycling and treatment system.

• elimination of arduous work and preservation of human capital in difficult environments.

Protection of operators

Increased productivity - Area = 7 m2/h.

Reduced lead times

Collection and treatment of waste

Sandblasting

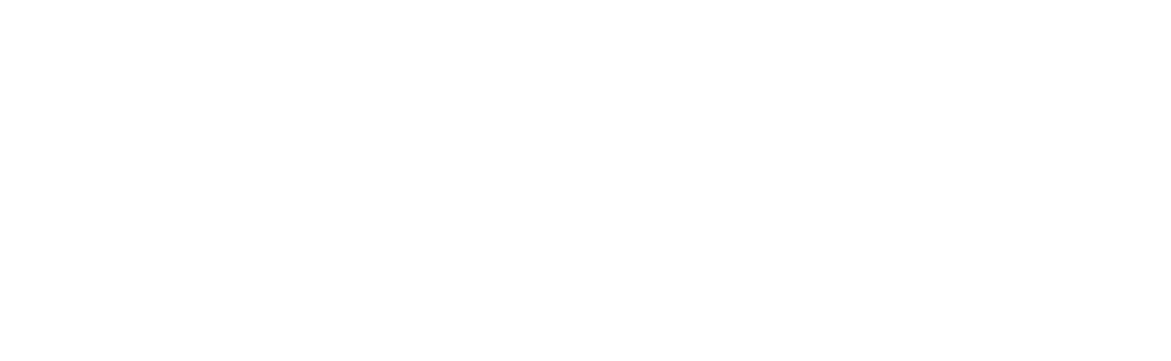

1 – UHP sandblasting chamber mounted on the robot tool holder

2 – UHP sandblasting system

3 – Silo and water treatment system to the container: depolution

4 – Suction system – Vacblast 45 Sibilia

5 – Nomad’o container

Equipment and technical data

- Closed circuit water treatment

Engine: Diesel Deutz 120 KW

Consumption: 16 L / h. (Fuel)

Max pressure: 2500 bar

Max flow: 27 L / min

Weight: 2400 Kg

Dimension (L x W x H): 4540 mm x 1930 x 2450

Motor: Electric 45 kW direct start

Vacuum: 0.6 bar

Max flow rate: 2100 m3 / h.

Weight: 2090 Kg

Dimension (L x W x H): 2450 mm x 1200 x 2320