Robot for ship hulls

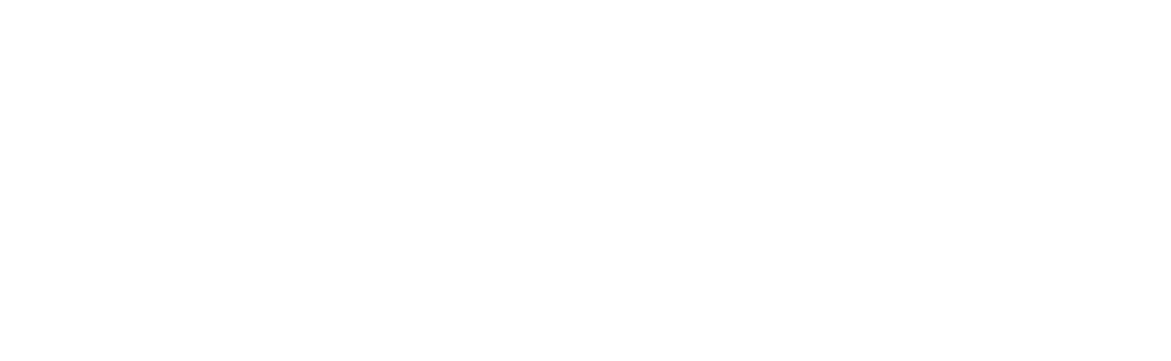

GreenDock Robot H28Our unique autonomous robot is a multi-function tool carrie:

washing, sandblasting and painting

robot with Toolholders multifunctional

• A head equipped with a Cartesian manipulator with its multiprocess tool support,

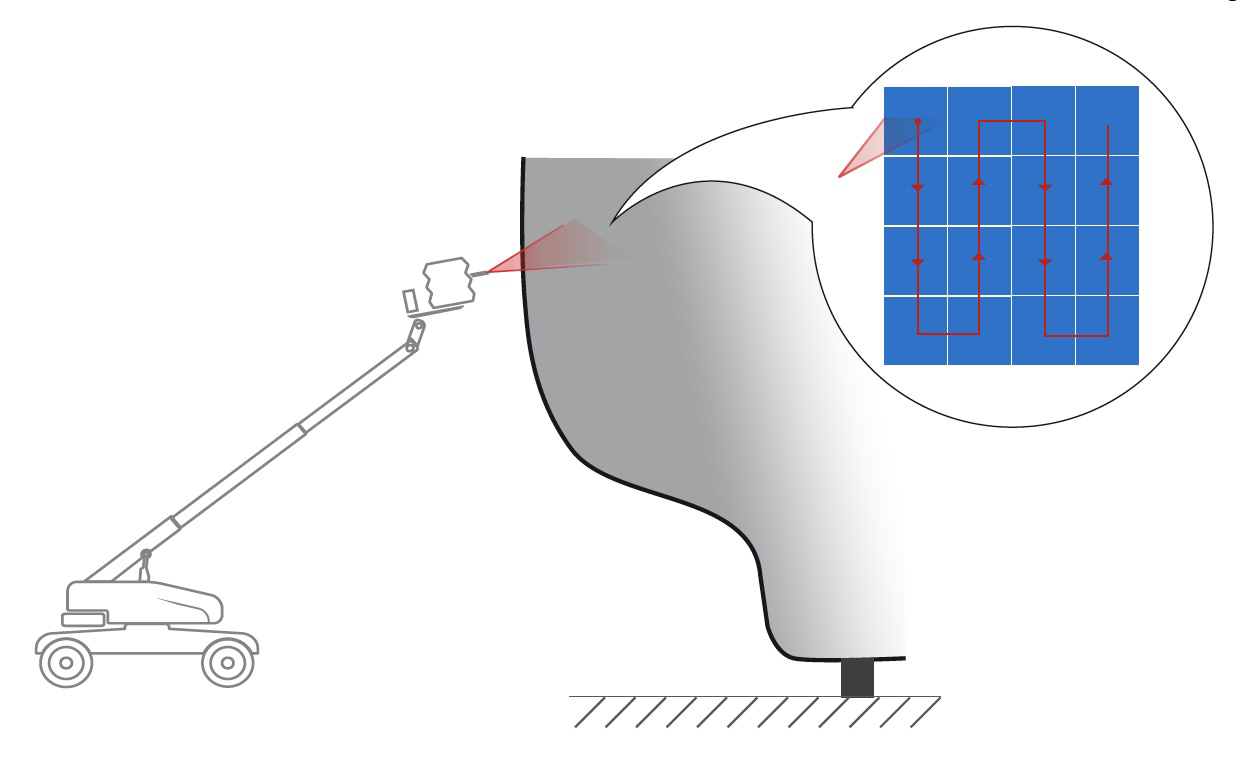

• A 28 m all-terrain diesel telescopic nacelle manipulator,

• A control command system with its sensors and actuators to control the 10 axes of the robot and the 2 axes of movement of the 4-wheel drive base.

Mobile base

A command control system with its sensors and actuators to control the 10 axes of the robot and the 2 axes of movement of the 4-wheel drive base.

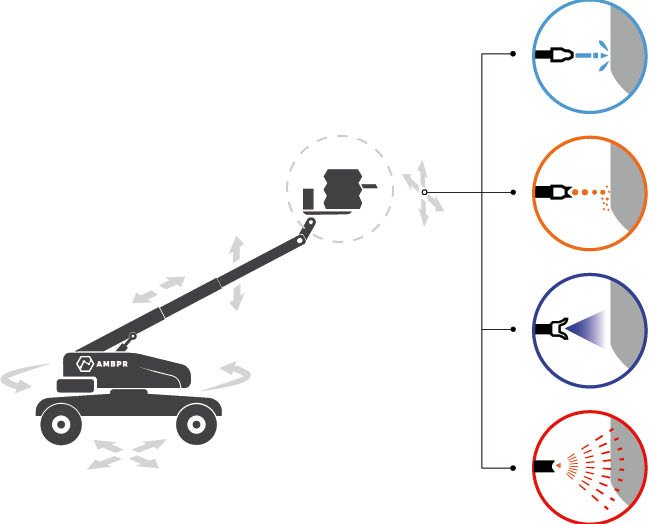

Detection and displacement process

The autonomy of the robot is acquired by a network of sensors which allows the nacelle to locate itself in its environment and to cover an area of approximately 150 m² in complete autonomy.

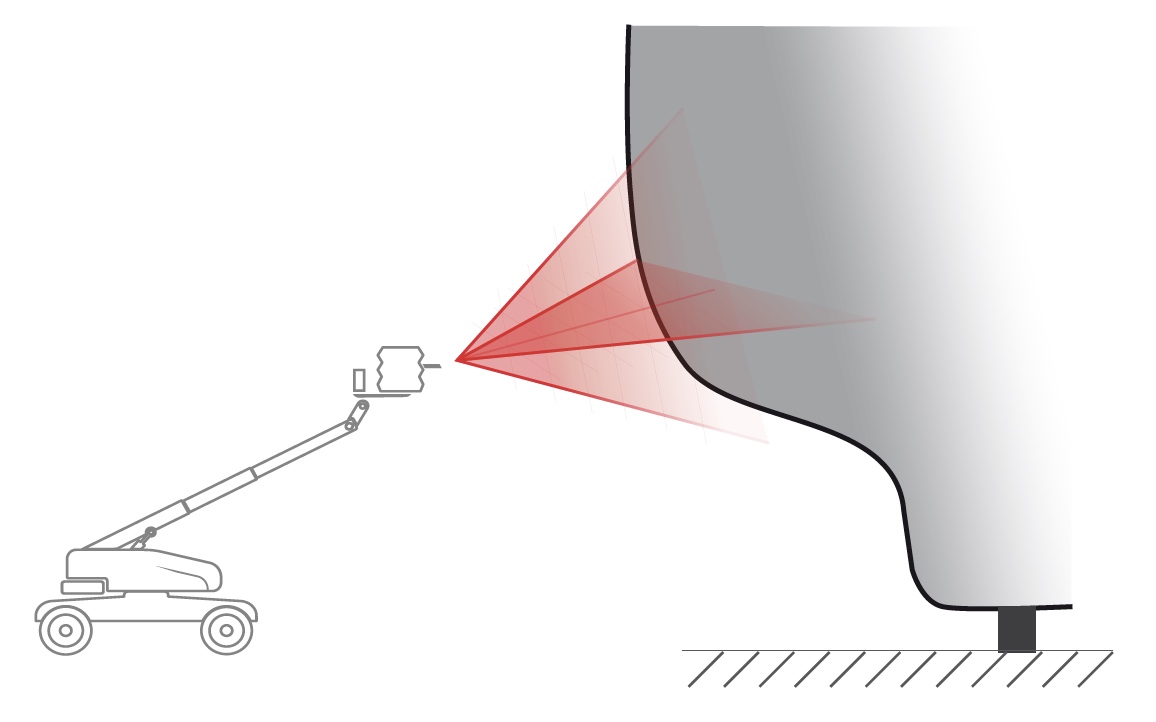

Hull profile tracking

The axes of the robot ensure correct positioning of the tool in relation to the surface to be treated.

Turret

Liftable up to 70° and deployable at 28 m.

Multiprocess

It integrates a robotic multifunction tool carrier which allows, from a single basic means, the individual implementation of operations:

washing, stripping, or paint application.

• UHP Sandblasting

• Abrasive Sandblasting

Inspection

Washing

Sandblasting

Painting

Inspection

For the treatment of spots, it is possible to configure the 2 dimensions of the rectangle.

The tool moves in the rectangle by succession of vertical bands with an adjustable overlapping rate.

Then, the robot moves the application rectangle to make a succession of vertical strips from top to bottom.

- Improved productivity and yields (reduced lead times).

- Improvement of working conditions and OHS of companions (elimination of accidents and exposure to harmful substances).

- Reduction of the environmental impact (quantity of waste and rejections).

- Improvement of the quality of work (perfect repeatability and control of the application).

- Autonomy in carrying out the work (the operator can monitor several machines with a simplified user interface without the need for programming knowledge).

Videos

Robot washing process shipyard – DAMEN