Process

The Sames Kremlin range of Airless sprayers are intended for spraying corrosion protection coating. AIRLESS spray equipment is extremely robust and adapts to the most difficult environments.

The application of industrial anti-corrosion paints offers many advantages to project owners:

• durability and increased efficiency and lifespan of industrial structures and infrastructures

• quality of spraying with stability of colors and enhancement of the work

• protection and reduces the effects of the external environment

• facilitates cleaning, the coating is washable which allows cleaning with high pressure water.

Spray quality

Increased productivity - Area: 100m2/h.

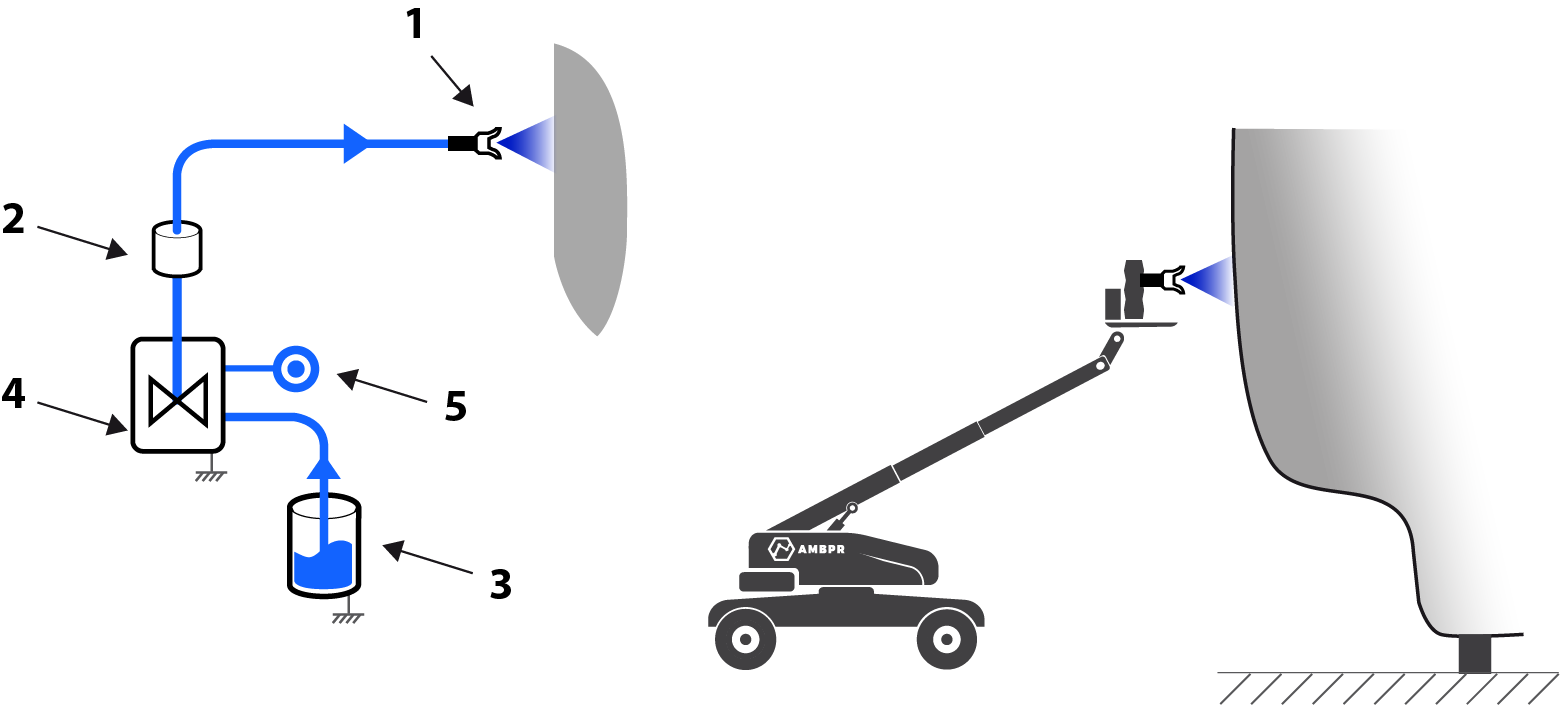

Reduce vessel downtime in dry dock

Récupération des C.O.V. (composés organiques volatils) par captation de l'overspray.

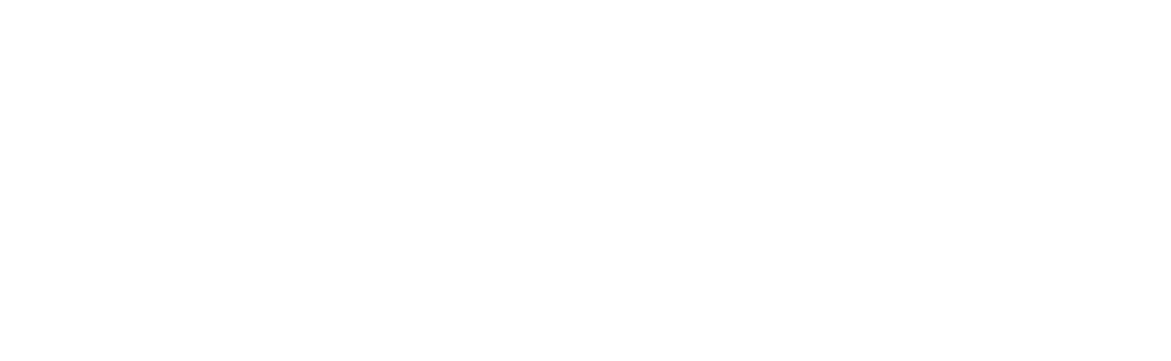

1 – High pressure gun with flat jet nozzle mounted on the tool holder of the robot

2 – High pressure regulator

3 – Paint tank

4 – High pressure pumping system

5 – Air compressor

Airless high pressure nozzle

Automatic unblocking system by rotation of the nozzle (SAMES KREMLIN) = Nozzle TIP-TOP

Pressure ratio: 72:1

Fluid pressure max. : 432 bar

Weight: 80kg

Nozzles: Airless catalog from SAMES KREMLIN

Dry air supply: cat’s head or Mal 3/4”BSP connection

5 bar min to 6 bar max / 2100 L/min min to 5000 L/min max